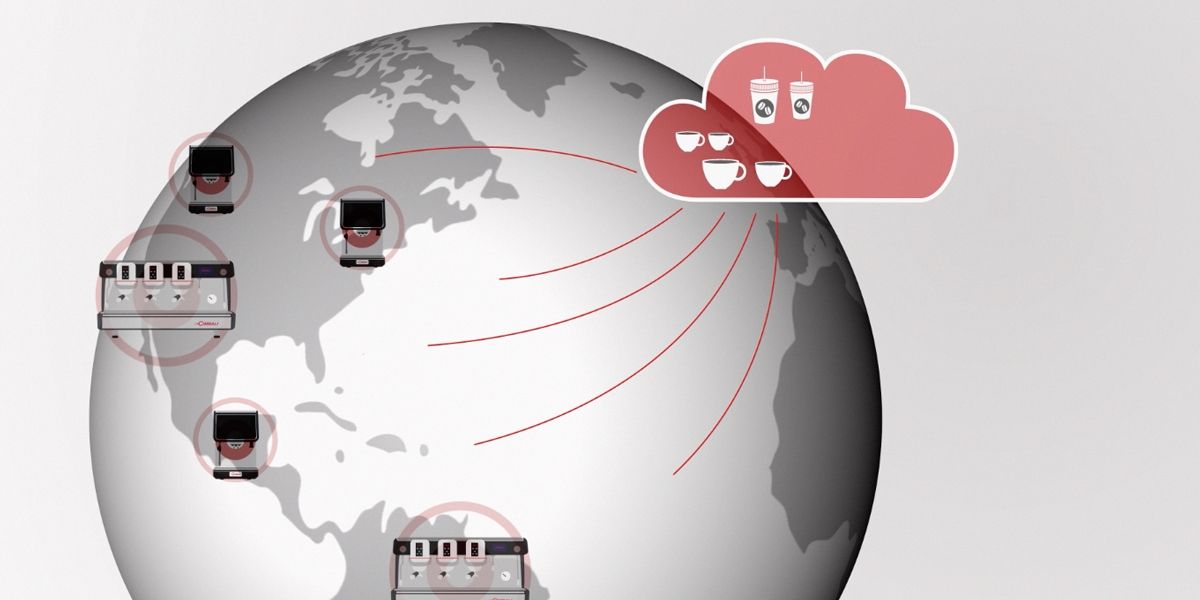

TELEMETRY

Data communication and remote monitoring of all the machine's functions and performance

What is it?

This technology enables data communication and remote monitoring of all the machine's functions and performance via a Wi-Fi link.

Features

The data, which are sent by the machine to a web platform, can be used for statistical consumption analysis of, for example, the number of drinks dispensed, both in total and per selection.

The technology also means that the machine can be monitored constantly, as it provides a real-time snapshot of all the machine’s parts and communicates any errors or malfunctions directly to the technician.

Benefits

Consumption monitoring

Control of dispensing parameters

Wash control and ongoing analysis

Analysis and prevention of malfunctions

Effective and efficient planning of maintenance operations

Application

Traditional and superautomatic

Bi-directionality

The great innovation in telemetry in the S range is the BI-DIRECTIONALITY of data communication.

This feature enables machine data communication to the web platform and allows operators to access the machine itself remotely via the web, to modify, for example, machine settings or dispensing parameters. Enables all machine parameters to be set remotely. It allows technicians to modify the drink dispensing parameters remotely, without needing to be physically present on the spot.

Security and Data Privacy

We adhere to the General Data Protection Regulation (GDPR).